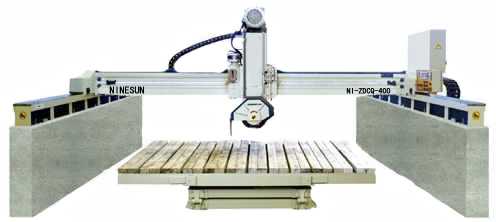

Profiling System

Infrared bridge cutting machine is equipped with 360-degree rotary table, adopting wide-span bridge type structure. Horizontal stone slicing can be achieved by moving the girder. The maximum blade vertical stroke can be up to 3.6m with flexibility in rotation, revise in positioning and stability in operation. This bridge cutting machine is used for cutting stone slabs, which is controlled by microcomputer with touch-sensitive operating system. The control is at the top as far as its reliability and its performances are concerned. A fine adjustable inverter controls the cut and return. The working bench can overturn by 85 degree. The bridge saw is equipped with a laser illumination system, which makes the disc adjustment easier. The mainframe of the stone cutting machine adopts imported frequency transducer to achieve step-less adjustment of cutting speed. The cutting dimensions are set by terminal input. Adopting monoblock crossbeam automatic moving technique, the stone cutting machine has a great improvement on working precision and stability, which is equipped with high quality imported electric components and high precision accessories. There're type 400 and 600, fixed blade and tilting blade for choice. With simple operation, high precision cutting, stable perform, the bridge cutting machine is particularly suited to high-value and large stone slates.

NI-ZDCQ-400

| Unit | ZDCQ-400 | ZDCQ-600 | |

| Max.working dimensions (L×W×H) | mm | 3200×3200×65 | 3200×3200×165 |

| Max.diameter of table | mm | 400 | 600 |

| Table dimensions(L×W) | mm | 3200×2000 | 3200×2000 |

| Table tilting degree | n° | 0-85 | 0-85 |

| Table rotating degree | n° | 90 | 360 |

| Main motor power | KW | 15 | 18.5 |

| Water consumption | m3/h | 4 | 4 |

| Overall dimensions(L×W×H) | mm | 6000×5000×2800 | 6000×5000×2800 |